The standardization and certification of processes are key when promoting technological development and encouraging a higher quality of service that companies provide to their customers, allowing the latter to have a clear reference on how a company works when deciding to hire their services.

For this reason, the role of the International Organization for Standardization (ISO) is fundamental, as it is the world’s most important developer of voluntary international standards. They offer solutions and best practices for almost all types of technology and business, helping companies and organizations increase performance while caring for consumers and the planet.

As defined by this organization, ISO 9001 “is a standard that establishes the requirements for a quality management system, helping companies and organizations to be more efficient and improve customer satisfaction.”

ISO 9001 is based on the idea of continuous improvement. It is designed to be flexible enough to be used by many different types of organisations, so it does not specify what the objectives related to “quality” or “meeting customer needs” should be.

According to Skillcast, this standard “is based on 7 quality management principles, which include having a strong focus on the client, the participation of the company’s management and a drive for continuous improvement”.

The seven quality management principles are:

1 – Customer orientation

2 – Leadership

3 – Commitment of people

4 – Process-based approach

5 – Improvement

6 – Evidence-based decision making

7 – Relationship Management

For its part, ISO 14001 certification also allows companies to address an environmental policy through standardized processes, the International Organization for Standardization defines it as “an internationally agreed standard that establishes the requirements for an environmental management system”, adding that the latter is the one that “helps organizations to identify, manage, monitor and control their environmental problems in a “holistic” way.

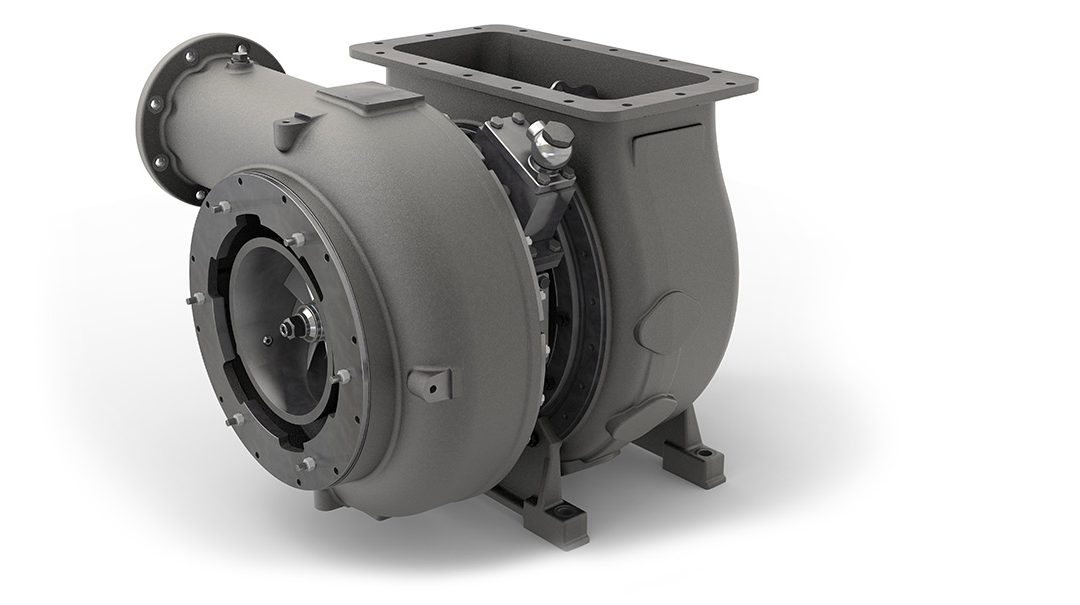

That is why these two certifications are essential for the turbocharger sector, where quality and efficiency have historically been the main objectives, to which is now added a growing need to protect the environment, not only through the final product, but also throughout all the processes carried out by companies in the sector.