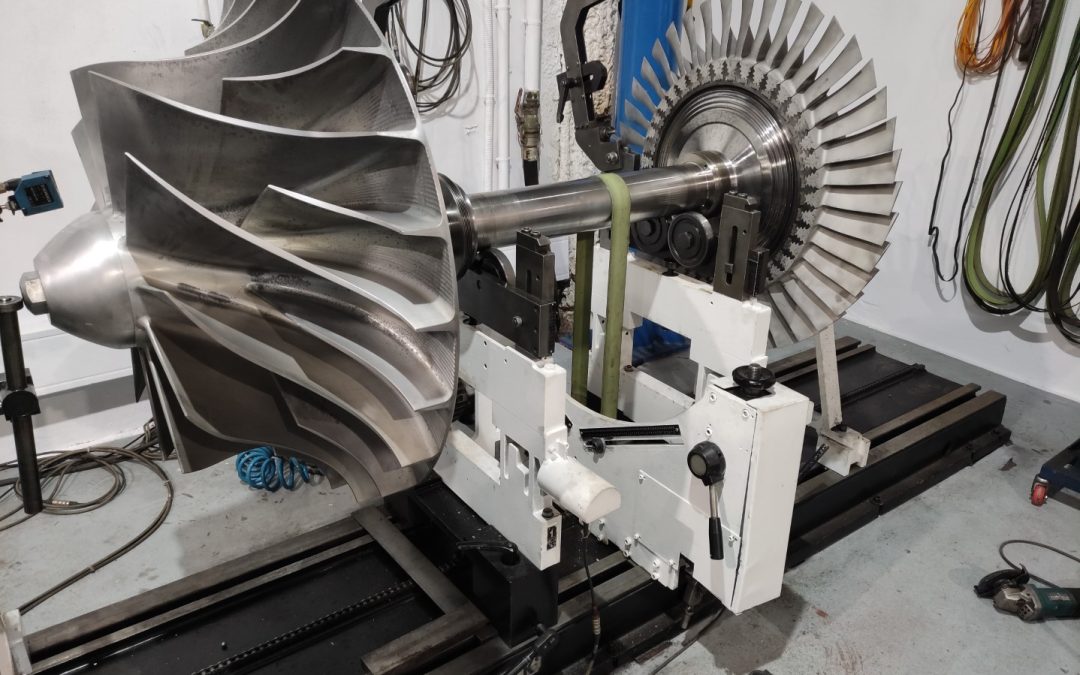

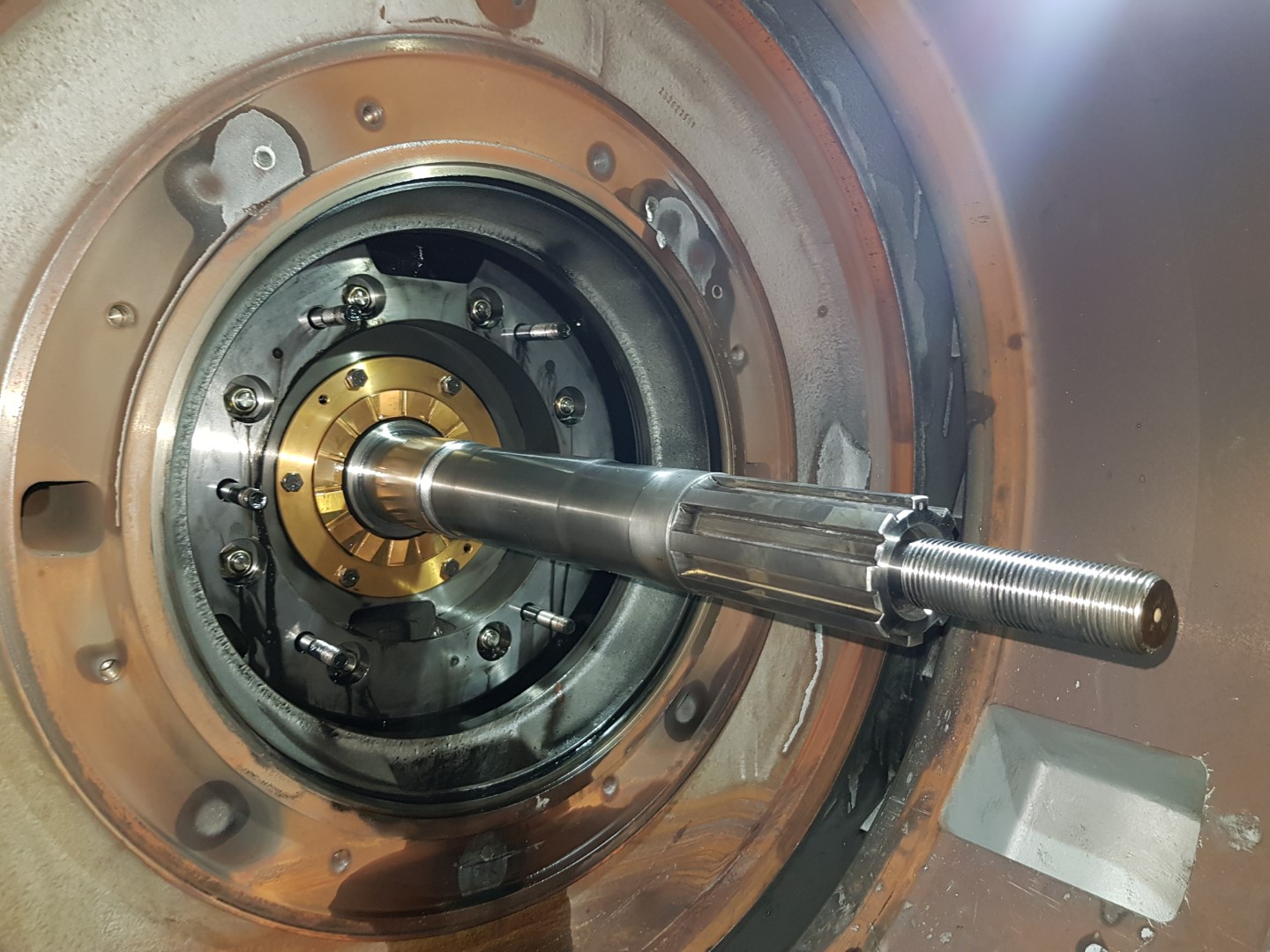

When talking about a TCA88, it is evident that we are dealing with a large-sized turbocharger that requires a highly skilled human team and adequate technical and workshop resources to carry out its maintenance. But when it comes to two units, the level of organization, experience, and effort required is considerably higher.

A few weeks ago, we had the privilege of successfully carrying out the maintenance of two TCA88 units during a technical stopover in the port of Algeciras. Our client took the opportunity to perform maintenance on the T/C during the express installation of the WBTS on their 45,000GT ship.

The maintenance work on the TCA88 was a challenge that demanded keeping the onboard and workshop teams active, ensuring a constant flow in the work chain: onboard disassembly, transportation to the workshop, reconditioning, assembly, and engine testing.

We want to take this opportunity to congratulate the entire team of technicians involved in the operation. Their dedication, experience, and effort made it possible to successfully complete the maintenance work. Great job by all!